What is Risk Based Inspection (RBI)?

RBI is a proven methodology that uses risk as the primary indicator of when to inspect an asset instead of time. It computes an asset’s Likelihood of Failure (LoF) compared to its Consequence of Failure (CoF) to determine which assets are most in need of inspection or maintenance, improving maintenance spend and reducing the likelihood of unplanned shutdowns.

In comparison to time-based inspection methods, RBI methodology prioritizes scheduling according to the assets that are most at risk. This allows you to prioritize inspection and maintenance budgets where it counts the most, rather than waste resources on unnecessary inspections for functional assets.

RBI methodology aligns with and supports API 580 and 581.

Antea RBI – Risk Based Inspection with Digital Twin Visualization

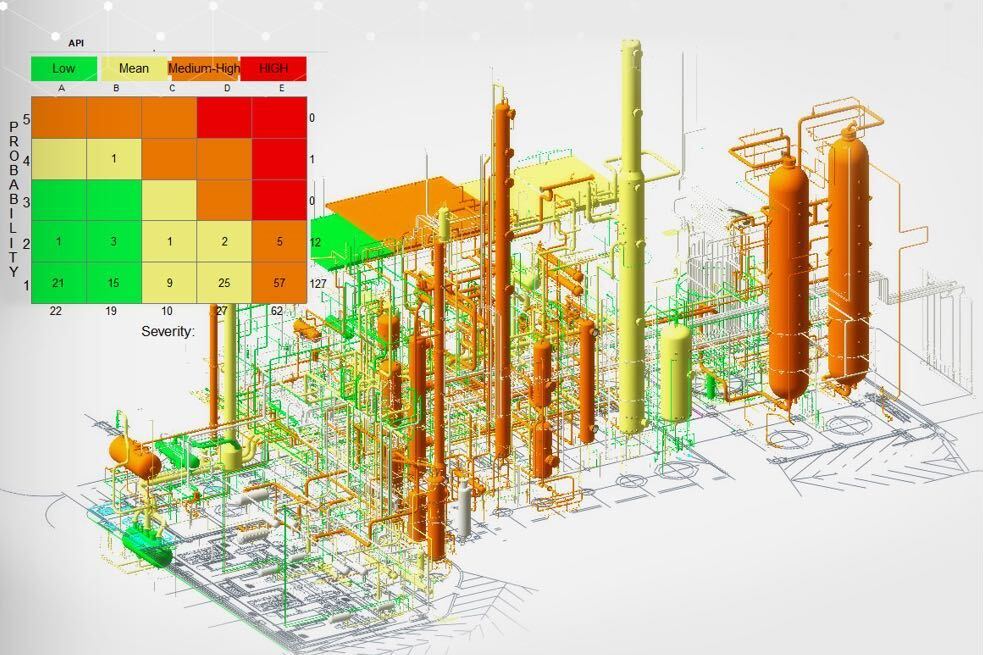

Perform qualitative, semi-quantitative and quantitative analyses to evaluate the probability and severity of failures in your plant. Leverage our industry-leading digital twin technology for interactive visualization – including a dynamic, virtual replica of your plant. RBI data is overlaid onto the digital twin and colored by risk level, providing an instant overview of asset health.

Antea RBI is validated to API 580/581 by a globally recognized certification body, ensuring seamless regulatory reporting and audit compliance.

Antea RBI is validated to API 580/581 by a globally recognized certification body, ensuring seamless regulatory reporting and audit compliance.