Overview

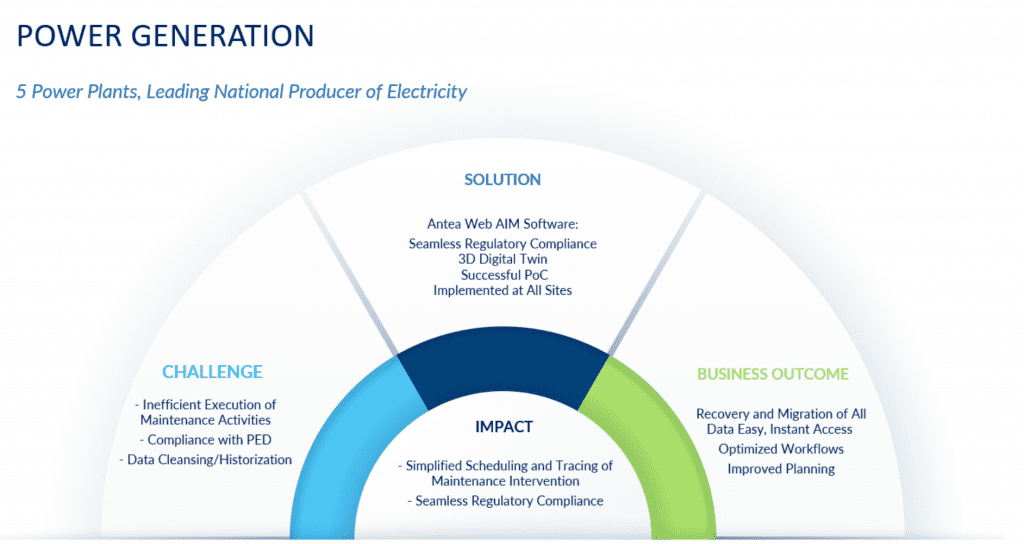

The company was having trouble and inefficiencies with:

- Execution of maintenance and data logging

- Activities directly related to the actual execution of maintenance interventions

- The tracking of data relating to maintenance events carried out on the individual components of the system

Impact

The pressure equipment is subject to the PED (Pressure Equipment Directive – European directive 2014/68 / EU), therefore it is mandatory to proceed with the checks and maintenance interventions according to the deadlines set by law in order to avoid penalties. Their current system did not support effective maintenance interventions and planning in order to properly adhere to this directive.

Solution

In 2017, the company had tested Antea Web AIM Software (formerly Palladio) during a proof of concept (PoC) test run and were impressed with the results. Given the good outcome of the PoC, the client expressed the need to equip itself with Antea Web solution on all sites, which in turn also conformed to the solution already adopted by the other group companies for asset integrity management (AIM).

The unparalleled technology inherent in Antea’s software with its 3D digital twin and mobility offerings granted the client unprecedented visualization and real-time access to asset conditions, delivering immediate time and cost savings. In addition, Antea provided the following support:

- Initial data loading:

- Asset list

- P&ID in CAD

- Floor plans

- Line specifications

- Sketches

- Axonometric

- Timetable

- Data Loading of field surveys and legal certifications

- Import P&IDs

- Import of personal data and schedule for the different items

- Attachment of reports, documents, photos in electronic format for each item

- 3D modeling and thickness monitoring location (TML) insertion

- Analysis of documents, integrity checks, and acquisition of signed minutes. Creation of the schedule and insertion of the related operations

- Project coordination and on-site meetings

- On-site training

Antea was able to overcome the hurdle of recovering all paper documentation, including difficult to find sources such as verbal, construction and thickness reports.

Results

As a result, the company experienced:

- Easy and quick to consult all information relating to any asset: from the datasheet, to the documents, to the schedule, to the operation history all the way up to the 3D model and TML.

- Antea Web made it possible for the sites to identify in advance the planning of future checks to be carried out, therefore anticipating costs for the following year and significantly improving maintenance planning & spending.

- The company was so impressed with the results that they are expanding their use of Antea Web to stack on modules for Electrical & Instrumentation, Waste Management Systems, and Fire Protection respectively.

- Data recovered during maintenance is directly loaded into the software, allowing for much faster data storage and optimization.