Latest Article

Dynamic RBI: Reinventing Risk-Based

Inspection for Real-Time Integrity

In today’s asset-intensive industries, inspection strategies have become a core defense against operational, financial, and safety risks. As assets age and process conditions grow more variable, operators face increasing pressure to make faster, more informed decisions to maintain reliability and compliance.

Risk-based inspection (RBI) remains the foundation of mechanical integrity programs, guiding inspection priorities through proven API 580 and 581 principles. Yet traditional RBI models are often static, updated at long intervals, while the risks they represent continue to evolve.

Dynamic RBI—also known as “RBI on the Fly”—advances these established methods into the real-time, data-driven era. By embedding risk logic within live data environments, operators can continuously align inspection plans with current asset conditions. The result is a stronger, more proactive approach to mechanical integrity—one that improves safety, efficiency, and decision confidence.

You’ll learn:

- How dynamic RBI extends traditional RBI principles into real-time operations

- Why continuous recalculation improves inspection accuracy and responsiveness

- The role of integration, digital maturity, and visualization in enabling dynamic programs

- Practical steps for evolving static RBI models into modern, data-connected systems

Download the full article to learn how dynamic RBI helps you optimize inspection resources, enhance reliability, and stay ahead of changing operational risks.

More Articles

| Title | Categories | Link | doc_categories_hfilter |

|---|---|---|---|

| Article-Data-Driven Decisions: Elevating Mechanical Integrity with Dynamic Strategies | Asset Integrity Management | asset-integrity-management | |

| Article-Enhancing Integrity Operating Windows with Real-Time Data to Improve Decision-Making | Asset Integrity Management | asset-integrity-management | |

| The Power of Data Visualization to Optimize Maintenance and Asset Integrity | Asset Integrity Management | asset-integrity-management | |

| How Digital Technology Enhances Reliability Centered Maintenance | Asset Integrity Management | asset-integrity-management | |

| How to Achieve Predictive Corrosion Management: The Role of Technology and IIoT for Predictive Analytics | Asset Integrity Management | asset-integrity-management | |

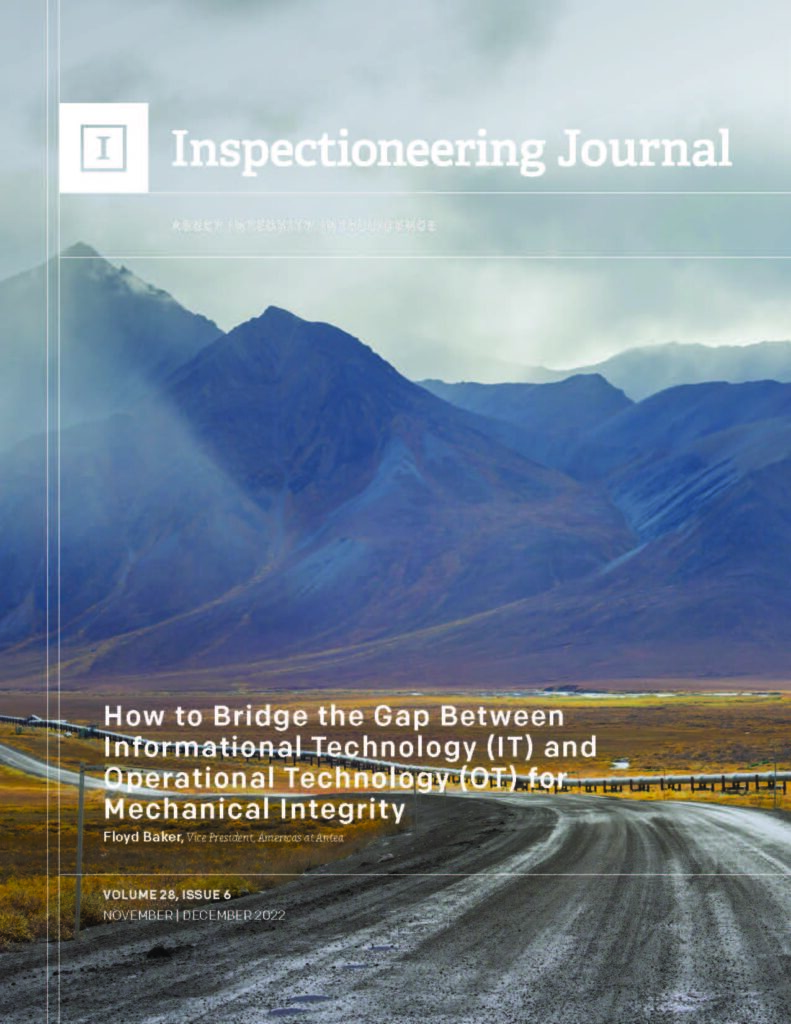

| How to Bridge the Gap Between Informational Technology (IT) and Operational Technology (OT) for Mechanical Integrity Programs | Asset Integrity Management | asset-integrity-management | |

| Merging AIM Software with Engineering Services for Total Asset Integrity Support | Asset Integrity Management | asset-integrity-management | |

| Digital Tools Preserve Asset Integrity | Asset Integrity Management | asset-integrity-management | |

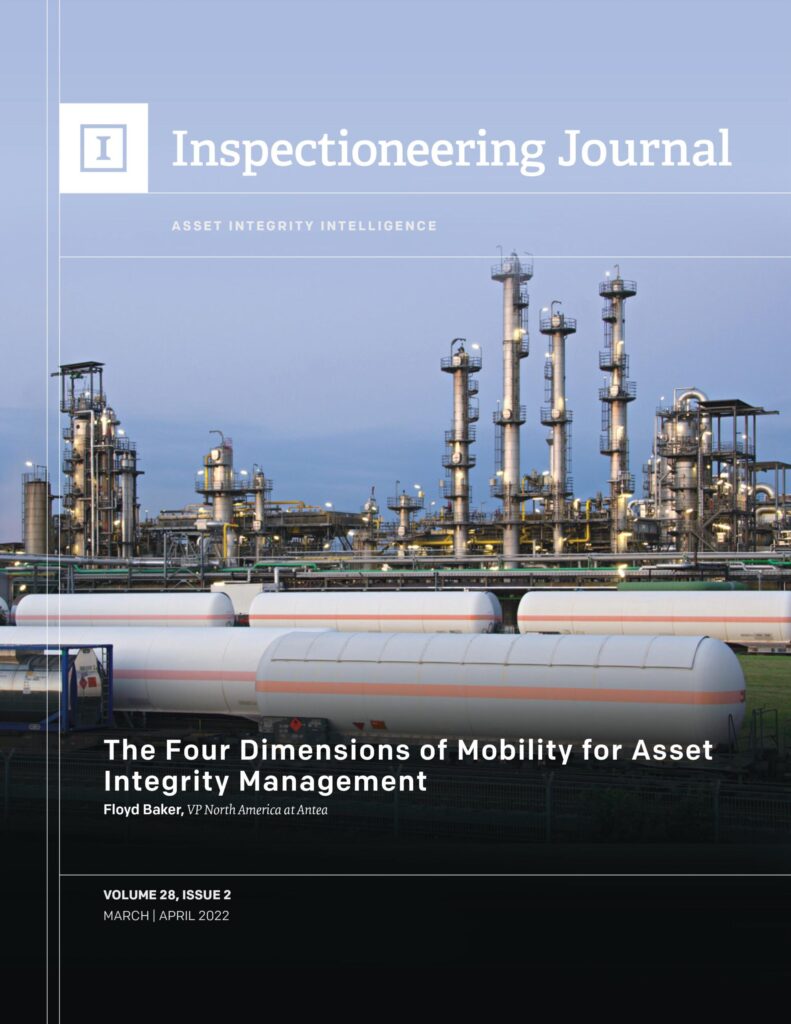

| The Four Dimensions of Mobility for Asset Integrity Management | Asset Integrity Management | asset-integrity-management | |

| Using Digital Twin for Terminal Asset Integrity Management | Digital Twin | digital-twin |